Today’s demanding operational and regulatory pressures call for the latest in automated processing systems and controls. The epileptic power supply in Nigeria has forced companies to use alternative power sources such as diesel generators. Diesel is a critical commodity that powers the operations of the majority, if not all industries in Nigeria and the Globe and companies in Nigeria consume large volumes of diesel on a monthly basis.

Today’s demanding operational and regulatory pressures call for the latest in automated processing systems and controls. The epileptic power supply in Nigeria has forced companies to use alternative power sources such as diesel generators. Diesel is a critical commodity that powers the operations of the majority, if not all industries in Nigeria and the Globe and companies in Nigeria consume large volumes of diesel on a monthly basis.

Nevertheless, the biggest issue organizations face is not just the cost of the diesel; it is also the rampant theft of the product. Industry data shows that organizations lose an average of thirty percent (30%) of all products bought through theft that leads to billions of Naira being lost on an annual basis by organizations.

Theft occurs at different stages in the supply chain Management. It occurs at the point of supply from manipulated meters, or suppliers working in collaboration with staff of the organization to manipulate figures, or occurs after accurate quantities have been supplied and staff steal diesel, They occur at other forms in the filling stations through incorrect recordings after dipping has occurred.

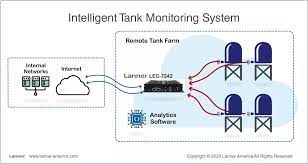

Knowing how much diesel is in your tanks is crucial to managing your assets efficiently. Depleted tanks equate to lost revenues, not to mention the redirection of time and resources that could be put to better use elsewhere. The right connection can make all the difference. Once a tank is connected to the cloud, your connected infrastructure becomes an intelligent infrastructure.

Our wireless tank monitoring systems are the most reliable and advanced systems in the industry today. We provide improved level measurement accuracy, making it possible to stop theft, reduce cost, save time, and ensure regulatory compliance, especially those governing electronic records for accuracy, reliability, and electronic reporting. Gauge's measurement technologies support these requirements better than anyone else’s.

Through the use of wireless sensors and cloud-based database software, remote tank monitoring allows you to stay up-to-date with how much of an asset you have, how much diesel you have, and when you need a top up. This enables you to make the best decisions for your business or project, increasing efficiency and reducing unnecessary costs.

Critical to any effective tank monitoring solution are sensors that monitor and report gas and liquid levels inside the storage tanks. When it comes to these sensors, the two cornerstones of success are accuracy and precision.

Accuracy refers to measurements that are close to the true value; in other words, measurements that are close to how much gas or liquid is in the tank. Accuracy measures correctness.

Precision refers to measurements that are close to each other; in other words, measurements that are similar and reproducible. Precision measures exactness.

Something can be accurate without being precise, and something can be precise without being accurate. For a remote telemetry system to be effective, each and every liquid level sensor must score well in both accuracy and precision. This is more difficult to achieve than one might assume, which is why Gauge supports a wide range of liquid-level sensor types. This enables our systems to achieve accurate and precise measurements for a variety of chemicals and liquids, while operating in virtually any location. Some examples of the tank level sensor types that we use include the following:

For applications that require a high level of accuracy, guided wave radar is the preferred method. Guided Wave Radar offers accuracy down to +/- 2MM and works in environments with dust, foam and heavy vapors. Guided Wave Radar can also be used to determine the interface between two media.

Ultrasonic Level measurement is another common sensor technology used for measuring liquid levels. It works using the “time of flight” principle, which bounces sound waves off of the top of the liquid using the speed of sound. This process of measuring the distance between the transducer and the surface uses the time required for an ultrasound pulse to travel from a transducer to the fluid surface and back.

The benefits of Ultrasonic Level sensors include: no contact with the liquid, less maintenance, and easy installation. The disadvantages are that they are subject to interference from heavy vapors, surface turmoil, foam, ambient noise, and temperature. For some mediums, this is not an issue. Gauge can help make that decision in collaboration with the clients.

Accurate remote monitoring sensors and versatile communication solutions are important for successful tank monitoring, but so is accessibility. In other words, is the tank monitoring software easy to use?

At Gauge, our answer is always “yes.”

Our TankAI system is an extremely powerful yet easy-to-use cloud-based monitoring software for tank-level monitoring. The platform accommodates a wide range of tank types, such as water, oil, chemical, diesel, and more. Furthermore, its ability to distinguish the type of tank and the medium being monitored allows us to deliver effective analytics, alerts, and reports.

Additionally, the TankAI monitoring platform allows remote tank management to send tank notification alerts. These notifications can be sent via email, smartphones, text messages, or even phone calls.